American Elevator - Table of Contents ........... ........... Grain Elevators - Table of Contents

2013 color photos

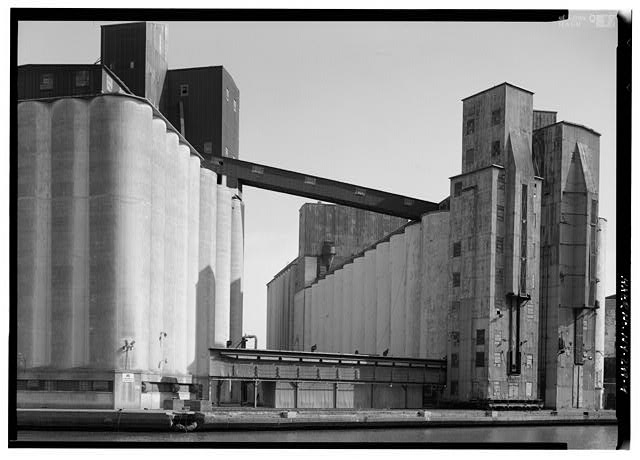

Marine Towers (North elevation)

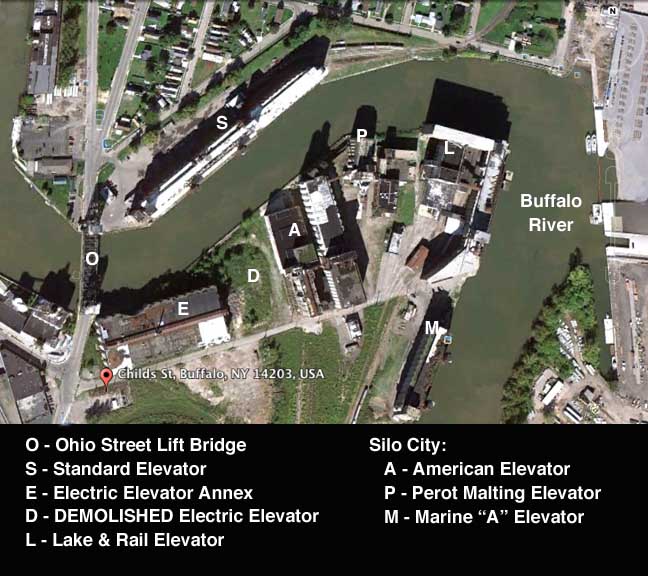

American Elevator / Russell-Miller Milling Company Elevator / Peavey Co. Elevator

87 Childs Street in the First Ward in Buffalo, NY

Part of Silo City

The main source of information about this elevator is found at HABS (online March 2013)

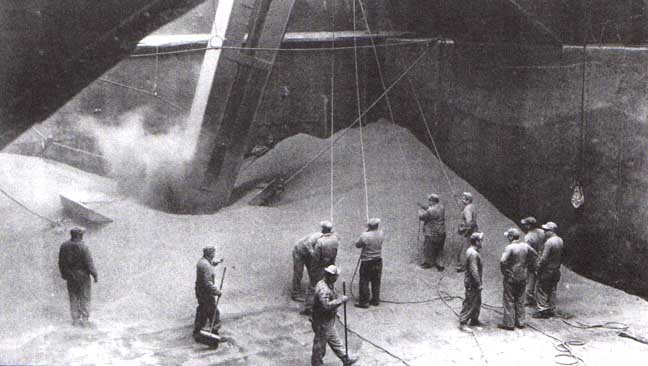

Marine tower: Houses the marine leg.

Marine leg: Includes a vertical conveyor belt made of leather or canvas and

equipped with buckets. The conveyor could be canted outward from the tower and lowered directly into the hold of

a waiting ship that was loaded with grain.

The grain would be emptied - "elevated" - up this leg to a scale where it was weighed before being distributed to large

storage bins.

The founding company, American Malting, was created in August 1897, to consolidate a large number of small malt houses under one combine. The trust was established to sell prepared malt to brewers more cheaply than they could purchase barley alone. The 1906 elevator was built to store and process malted barley for beers. The Volsted Act (Prohibition) ruined the business. The complex included one fixed marine tower ("marine leg").

"In the interval between Perot's Buffalo founding in 1907 and American

Malting's final dissolution in 1922, the smaller malt house received

all of its barley, the raw material from which malt is derived,via

railroad. The Perot Elevator had been constructed without any marine

legs despite the malting company's desirable riverside location.

"In 1922 the American Malting Elevator was sold to ... [the Russell-Miller company]. On July 1, 1922, an agreement was struck between Perot and ... [the Russell-Miller company] for the latter elevator to handle water-borne shipments for Perot. In 1933 a successor agreement between Perot and ... [the Russell-Miller company] established that part of Perot's land would be used to erect a movable marine tower plus a 100' dock. These would be built by Perot but used by American Malting. Perot's barley shipments were then conveyed to Perot from American via an overhead belting system." - HABS (online March 2013)

In 1921, the elevator was taken over by the Russell-Miller company who used the mill to produce its Occident-brand flour. By the late 1920s, the company owned 135 country elevators and three terminal elevators including the American. Since the neighboring Perot Malting Elevator was no longer a barley malting competitor, Russell-Miller sold barley to Perot via the overhead conveyor gallery.

In

the early 1950s, Russell-Miller was bought out by Peavey Corporation,

the sixth largest grain dealer in the world. Peavey improved the

elevator and made the mill the world's largest pneumatic flouring

processor.

Model of Joseph Dart's original wooden steam-powered grain elevator on display in the Buffalo History Museum. Dart added a second marine leg in 1846 so that 2 different ships could be unloaded at the same time, one on the Buffalo River, one on the Evans Ship Canal. The two towers house the marine legs which include a vertical conveyor belt made of leather or canvas and

equipped with buckets. The conveyor could be canted outward from the tower and lowered directly into the hold of

a waiting ship that was loaded with grain.

The grain would be emptied - "elevated" - up this leg to a scale where it was weighed before being distributed to large

storage bins. There, grain would be stored until sold.

Moving conveyors were steam powered fueled by coal.

|

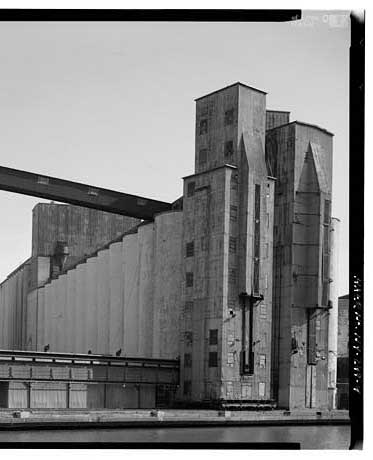

Find American Elevator on map. The two American marine towers are located next to the Buffalo River.  East elevation - American Elevator Left: Two marine legs (black in photo) ..... Silos (white) ..... Brick building is the flour mill  American Elevator: Two marine legs (black in photo) at left ... Round silos/bins in elevator ... Brick flour mill.  North elevation: two marine legs. Photo taken on Buffalo River. A Marine tower - "marine leg" - can

either be in a fixed position, a "stiff leg," or movable, a

"loose leg" on car wheels. With a fixed tower the lake boat must be

moved so the marine leg can get all the grain from the holds. The

movable tower can reach a number of holds.

The original 1906 American Elevator building was fitted with a fixed marine tower - the one to the right in the illustration. The tower is of structural steel clad in corrugated iron. The movable tower to the left, which ran on rail tracks between the existing fixed tower and the Perot Elevator (off the photo to the left), was added in 1922 when Russell-Miller Milling Company purchased American and converted it to flour milling.

This is an edited/cropped photo. Photo source: 1994, by Jet Lowe, found on HABS (online March 2013).

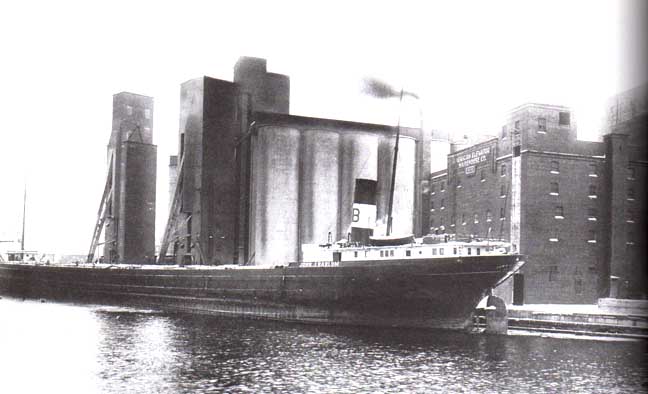

North elevation: two marine legs. Photo taken on Buffalo River.  The two marine legs of the American Elevator have been lowered into a ship's hold and are emptying the grain into the elevator.  "Scoopers" in the hold of a ship assist the marine leg with the unloading of grain into the elevator.  Spiral staircase in the American Elevator marine tower  Visitor in the American Elevator marine tower. Note the wheels for canting the marine legs out and into a ships's hold for grain unloading.  Side view (looking west) of the movable marine leg.  Note the white buckets on the marine leg. The buckets would elevate grain from the hold of ship up into the workhouse. In this photo, the steel enclosing the belt and buckets has fallen off.  Between the original fixed marine leg at left and the later movable marine leg at right. The movable leg moves on rails.  Between the 1907 fixed marine leg at left and the 1922 movable marine leg at right. The movable leg moves on rails.  Movable marine leg.  |

Left: Perot Malting Elevator ... Right: American Elevator. Photo taken on Buffalo River.

Note overhead conveyor gallery between the two elevators. Russell-Miller unloaded barley from ships and sold the barley to Perot. Perot, at left, does not have marine legs and so could not unload ships. Prior to 1922, Perot bought barley shipped by rail. The movable tower to the left, which ran on rail tracks between the existing fixed tower and the Perot Elevator, was added in 1922 when Russell-Miller Milling Company purchased American and converted it to flour milling. Photo source: 1994, by Jet Lowe, found on HABS (online March 2013)  The steel cable would have been attached to the movable leg and used to move the leg to another section(s) of the docked ship. Concrete building: Perot Malting Elevator. The steel structure at the right served as a closed area to horizontally convey barley into the American elevator. |