Burt Co. / 500 Seneca - Table of Contents

F. N. Burt Co. / Five Hundred Seneca

500 Seneca Street, Buffalo NY

Five Hundred Seneca - Official Website

Reprint Buffalo: Lake City in Niagara Land By Richard C. Brown and Bob Watson USA: Windsor Publications, 1981, p. 270  |

|

Excerpts

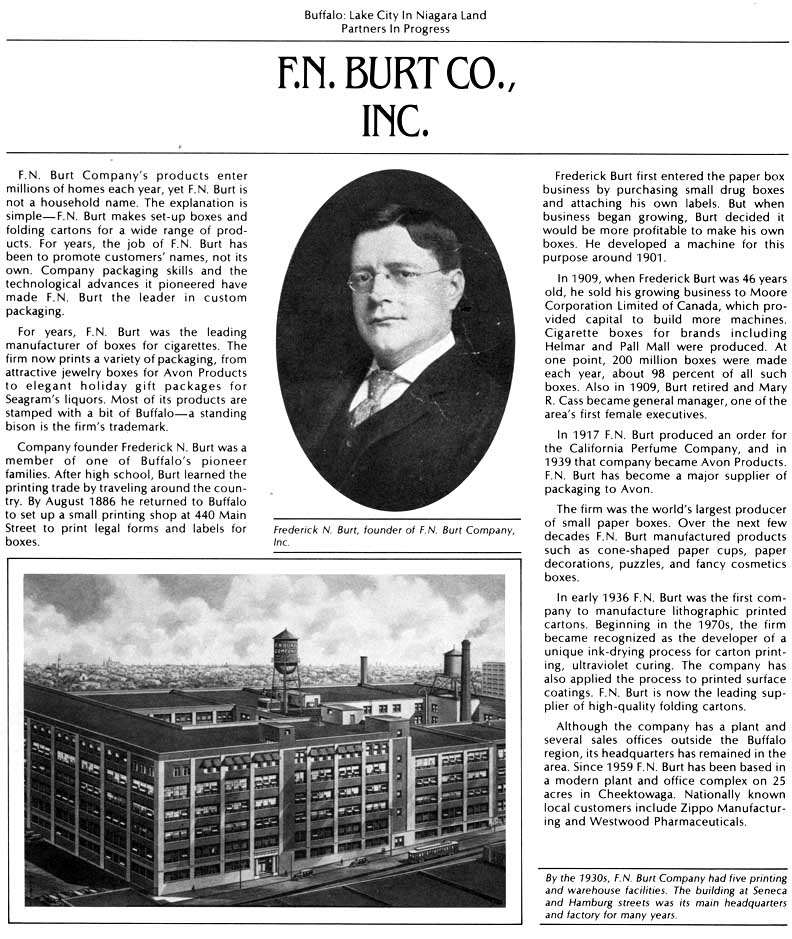

F. N. Burt was World's Largest Paper Box Manufacturer By Chris Hawley The Hydraulics Press March 16, 2009 Did you know the largest manufacturer of small paper boxes in the world was in Buffalo? Consider yourself now in the know! The F. N. Burt Company, whose sprawling factory complex at Seneca and Hamburg streets churned out upwards of four million boxes a day, was one of the largest employers in the Hydraulics and one of the shining lights of Buffalo industry. F. N. Burt, an innovator in graphic design, was one of the most respected box manufacturers on the planet. Renowned for the glamour and sophistication of its manufactures, the company experienced tremendous growth in the early 20th century that coincided with, as well as contributed to, the emergence of the stylized box as an advertising vehicle for mass-produced consumer goods. Its prodigious, 400,000 sq. ft. factory complex is entirely intact - every building it ever constructed on Seneca Street from 1901-1927 still stands, a miracle by any standard in industrial heritage preservation The company, symbol of Buffalo's progressive outlook at the early 20th century, made one particularly groundbreaking move in 1909 when it hired a female, Mary R. Cass, to be general manager of the plant - at a time when she was forbidden to vote in national elections and women were unknown in leadership positions at American factories. The fabulous Mary Cass, who almost single-handedly led the transformation of the small printing company to a manufacturing interest of world significance, was for the next twenty-five years one of the country's leading business executives. The plant was shuttered in 1959, the year the East Buffalo section of the Niagara Thruway opened and the company moved its factory operations to new facilities in suburban Cheektowaga. The complex, though vacant, is in sound and reusable condition, and is now [2009] owned by the Buffalo-based New Era Cap Co., one of the world's leading baseball cap manufacturers. A Buffalo Courier Express article printed September 21, 1952, has the plant's story: Burt Co. is World's Largest Maker of Small Set-up Boxes: Three to Four Million Units a Day

By Lee Griggs Ever think twice about a box? Probably not. Boxes are so common that few people think much about them except the ones who make them. Boxes are everywhere. They're convenient. There's a box for every use, but there's more to boxmaking than meets the eye. The world's largest manufacturer of small setup boxes operates right here in Buffalo. The F. N. Burt Co., a wholly owned subsidiary of the Moore Corp., Ltd., produces between 3,000,000 to 4,000,000 box units in every two-shift day. Burt operates a huge setup plant at Seneca and Hamburg, a folding carton plant at Main and Bryant, and a large warehouse on Babcock St., complete with rail outlet via the Pennsylvania Railroad. All of Burt's work is to custom order. Many customers renew their orders year after year, but colors, shapes and styles of boxes change constantly, presenting new problems for the company, which designs all of its own fully automatic boxmaking machinery. Burt's setup box volume is divided roughly into three equal parts. These categories are cigaret, cosmetic and pharmaceutical boxes, most of them specially designed. These are the basic types, but Burt boxes contain everything from face powder, mascara, pills and tooth powder to shoe polish, typewriter ribbons, fishing lures and phonograph needles. The variety is astonishing. Some setup boxes are square or oblong. Others are round or oval. Burt is an extensive maker of oval and odd shaped boxes because no one has the ingenious machinery necessary to do it automatically, the only way it pays. In addition to making boxes directly to customer order, the firm also makes up drug boxes for resale to the stock drug trade. F. N. Burt, founder of the company, went into business in August of 1886, but not making boxes. He was printing legal briefs at first and then expanded to include the printing of drug labels. When Burt finally got into boxmaking at 440 Main St. in 1896, his product was brightwood folding boxes, not the present setup type for which the firm is so well known today. Five years later, the first of the Seneca St. units was built, facing Hamburg. This started a long line of expansions on that site, finally completed in 1927 to provide six floors and 400,000 square feet of space. The Main-Bryant plant, occupied in 1935 to accommodate customer demand for folding cartons, offers another 100,000 square feet. Miss Cass becomes manager Burt sold the business to the Moore interests in 1909 and retired the following year. His successor was Mary R. Cass, who served as general manager for 25 years and was considered one of the country's most able business women. Prior to World War I the big box item was cigarets. The company devised special machinery to turn out automatically some 250,000,000 of these hardwood boxes before excise taxes and the advent of the cup package killed the market. Now boxes are coming back strong. The public has accepted enthusiastically the Regent and Parliament type of cigaret box, which either opens from the top or slides out. Burt makes millions of boxes for both of these manufacturers. As the cigaret business fell off in the 20s, cosmetic and pharmaceutical box demand took up the slack. Burt began packaging face powder in solid round and square setup boxes. The cosmetic trade soon supplanted cigaret boxes as the biggest production item. Today Burt is still the largest supplier to the cosmetic industry. Many modern cosmetic boxes have transparent cellophane exposure panels. Others are decorated with Burt's extensive lamlac finish. Powder boxes have transparent drums fitting inside the box's base walls to prevent the powder from shifting, just one of the challenges Burt had to overcome to meet successfully the precise packaging demands of customers. Materials arrive for processing from all parts of the country in rolls or flat sheets. Stock is then lined to specifications, after which specially designed and built machines for manufacturing do the glueing, labeling, stamping and assembling at tremendous speeds. Paper, board and glue are the chief boxmaking ingredients. All these are subject to the effects of moisture, but Burt controls the conditions of manufacture so closely that parts can be fitted within a 64th of an inch. The folding carton business at Main and Bryant comprises from 15 to 20 per cent of the total sales volume, depending on the trends of business. The plant offers a high grade lithographing service for cartons, producing a better quality than the letter-press method used by competitors. In addition to making boxes, Burt will also furnish any prospective customer with a special consultation service to help work out effective designs, colors, print and type matter for merchandising. Manufacturers for the retail trade know the value of an attractive package as a stimulant to produce sales, and many concerns call on Burt's know-how, born of long experience in box designing. Machinegun parts During World War II, Burt made a direct contribution to the war effort as a sub-contractor producing machinegun parts under government order. The company also produced 1,000,000 special cartons a day for the Medical Corps. But there was another contribution. If Burt hadn't come up with wartime paper substitute cartons for metal tins used to carry thousands of products during peacetime, many manufacturers might have been hard pressed to continue in operation. Burt made jar caps from cardboard to replace metal ones, and even threaded them. Millions of aspirin boxes, usually made of tin, were produced from paper. So were tooth powder containers as the Seneca St. plant worked around the clock. Brass was short and millions of paper lipsticks were made. Pension plan for employees The company has always prided itself on good labor relations. The product is light, clean and easy to handle, making work more enjoyable. Burt was the first box company to set up a fully funded pension plan for employees. As a result, turnovers have been slowed. Nearly half the Burt workers have been with the company more than 15 years, 15 per cent of them over 25 years and a rugged handful over half a century. Today the trend is toward ever more efficient machine production. High labor costs have made machine production necessary to profitable operation. Manufacturing speeds have been increased steadily over the last 15 years as Burt continues to improve the quality of its vital service to retail manufacturers throughout the nation. |

|

July 27, 2012

Recently, the debate over inequality between men and women in the workforce was revitalized, with some economists arguing that it is individual choice, and not institutionalized sexism that causes this discrepancy in pay. Still, even today, there are only 18 women heading Fortune 500 companies, and that is the highest it has ever been. As 2019 and the 100 year anniversary of Women’s Suffrage approaches, this is a good opportunity to look back at some of the pioneers for women in business. One such woman, Mary Cass, rose to prominence as the head of the F.N. Burt box company at the turn of the 20th century. F.N. Burt was founded as a printing and label company in 1886, but in the following decades, switched to box making to capitalize on the nearby Hydraulics neighborhood, the manufacturing and shipping center of Buffalo during the late 19th century. By 1901, they had gone from a small, one-press shop with 8 employees, to an enormous facility at 500 Seneca, where they were able to manufacture enough boxes to become one of the leading manufacturers in the country. In 1909, after two expansions of their factory, the company was bought by Moore Corp, a Toronto-based business-forms company that needed box manufacturing for their own shipment needs. Fred N. Burt, as he turned over the company, recommended that Mary Cass take over managing the company’s factories.  Mary Cass, General Manager of F.N Burt Box Company This was almost a decade before Women’s Suffrage would be achieved however. Ms. Cass wasn’t the first woman executive, but she certainly was one of the most prominent, heading one of the largest manufacturing facilities in the country, for an industry that had experienced 43% growth in the decade. Under Mary Cass, the value of F.N. Burt skyrocketed. She oversaw several further expansions of their factory, as well as the expansion to other factories throughout Buffalo. F.N. Burt became one of the leading suppliers of cases for cosmetics, cigarettes, and other industries. By 1921, the company employed 2,500, and was worth almost $3,000,000. At a time when most men did not even know how to drive, Mary Cass was an avid motorist. She played golf, and never married, but as a Rotarian article wrote in 1918, she still enjoyed the “womanly” pleasures of dancing, and going to the theatre. While the Rotarian article comes off as a back-handed compliment, the celebrations in Ms. Cass’ honor in 1916 and 1921 for her 25th and 30th anniversaries with the company were far from that. At her 30th anniversary, she was the only woman at the event, and the praise of Samuel Moore, the president of the company, reveals how highly she was regarded; "She is the embodiment of good judgment. The fact that all you men have come here tonight, and many have come a great distance, is tribute enough to her success." Though she was honored with her inclusion on the 1984 YWCA Corporate Award as a pioneer woman in her field, today Mary Cass does not seem to garner much attention. This, despite all she achieved with F.N. Burt, as well as her role as one of the founding members of the Zonta Club, a women’s advocacy group that began in Buffalo, and today has more than 30,000 members in 63 countries. As we approach the century mark for Women’s Suffrage, it is important to acknowledge not only the women whose activism changed the political world, but the women who embodied this spirit of equality, and forced the world to accept them. Mary Cass’s position with the F.N. Burt Company epitomizes that effort, and she should be remembered as an important figure in Buffalo’s business history, as well as for her role in the Women’s Rights movement. |

Excerpts More Apartments Plus Distillery for 500 Seneca Street By WCPerspective Buffalo Rising Aug 25, 2014 The development team behind the repurposing of 500 Seneca Street

have doubled the number of planned apartments and signed a distillery

to occupy part of the complex. Savarino Companies and Frontier Group of

Companies are redeveloping what was originally the F.N. Burt Company

box manufacturing plant and later used by New Era Cap Co. into a mixed

use complex. The property is listed on the National Register of

Historic places and the project is utilizing historic preservation tax

credits.

‘Hydraulics Lofts,’ the residential component of the complex, has doubled in scope from an original 55 units to now 110 luxury and corporate apartments. Of the wave of conversion and loft projects, only the Lafayette Hotel has a higher number of units at 115. Sizes and rents range from a 560 sq.ft. second floor studio for $555 to $2,700 for a 3,000 sq.ft., top floor corner apartment. “We conducted a market study and it made sense to add them,” says Samuel J. Savarino, President and Chief Executive Officer of Savarino Companies. “With the 31 apartments planned across the street [The Square at Larkinville], this neighborhood will soon have 150 new residential units. The area will become more active.” The residences will occupy the oldest, wood-framed portion of the complex at Seneca and Hamburg Streets and also large portions of the second and third floors. There will be 20 different unit layouts, all with an open layout, high ceilings, and exterior exposed brick walls. Apartments will have high-end fixtures and finishes with either sealed and polished concrete floors or restored wood floors. Even the smallest units will feature at least one set of 8’ tall by 19’ wide operable factory windows or 6’ tall by 16’ wide operable ganged sash windows providing abundant natural light. Entrance corridors will have views into an interior atrium. Transoms above entrance doors will take advantage of the natural light from the interior atrium. Tenants will have 24/7 access to the building’s fitness center, exterior courtyard, and interior atrium. The courtyard will feature trees, gardens, and sitting areas and will have direct access to Myrtle Street. Apartments have either an in-unit washer/dryer hookup or semi-private laundry facilities which will be located in close proximity to each unit. Dedicated elevators will serve the residential component with a visitor entrance on Seneca Street. Apartment pre-leasing will begin shortly and occupancy is scheduled for next August. Savarino Construction is general contractor for the project that will be managed by Savarino Properties when completed. Chaintreuil Jensen Stark is architect and Preservation Studios is handling the tax credit certification work. On the commercial side, Savarino says that 44 percent of the planned commercial and retail space in the building has been leased to seven tenants. Adding to the unique mix of the building, a start-up distillery has recently agreed to occupy a portion of the first floor. The distillery, yet to be named, will manufacture spirits on site and is being run by Canisius grad Bobby Finan. In addition to a manufacturing area, Finan’s space will include a showroom and tasting area which will be located in a windowed mezzanine overlooking the distilling floor. The mezzanine will have an entrance on Seneca Street. Both visitors and passersby will be able to view the distillery operations though large street level windows. Other commercial tenants include Frontier Industrial Services, Frontier Group of Companies, Savarino Properties, and the BCOME Buffalo job training program. Other tenants have signed leases but have decided not to go public with their moves just yet. Offices will feature loft-style finishes with large exterior windows. Balconies are planned for the western façade facing downtown and can be added elsewhere if tenants desire them. Many artifacts recovered from 500 Seneca will be restored and displayed in the lobbies and corridors of the building. There are plans for a European style café/bistro for residential and commercial tenants immediately adjacent to the interior atrium. The café will serve specialty coffee items, wine, beer and spirits, as well as prepared and “grab and go” food. Catering services will be available. A full-service spa and restaurant are also planned for the first floor. 9,000 sq.ft. of space for individual climate-controlled storage units for both commercial and residential tenants will be available. Building tenants will also have secure, free parking. Commercial tenants are scheduled to being occupying their space in March [2015]. Residential Leasing: Alex Burgos, Savarino Companies, alexb@savarinocompanies.com or 716.332.5959

Project Information:Kevin Hays, Savarino Companies,

Chris Wietig, Frontier Group of Companies, cwietig@fic-services.com |

Samuel J. Savarino Photo taken on April 1, 2015, at the Working For Downtown: Buffalo Talks Speakers Series at the Buffalo Central Library  Photo taken April 2015 |